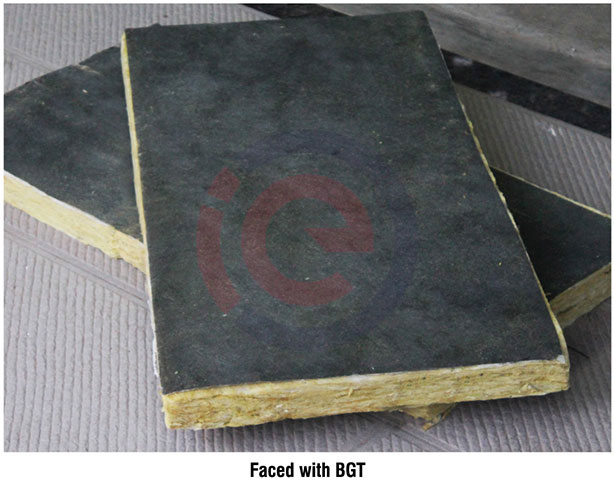

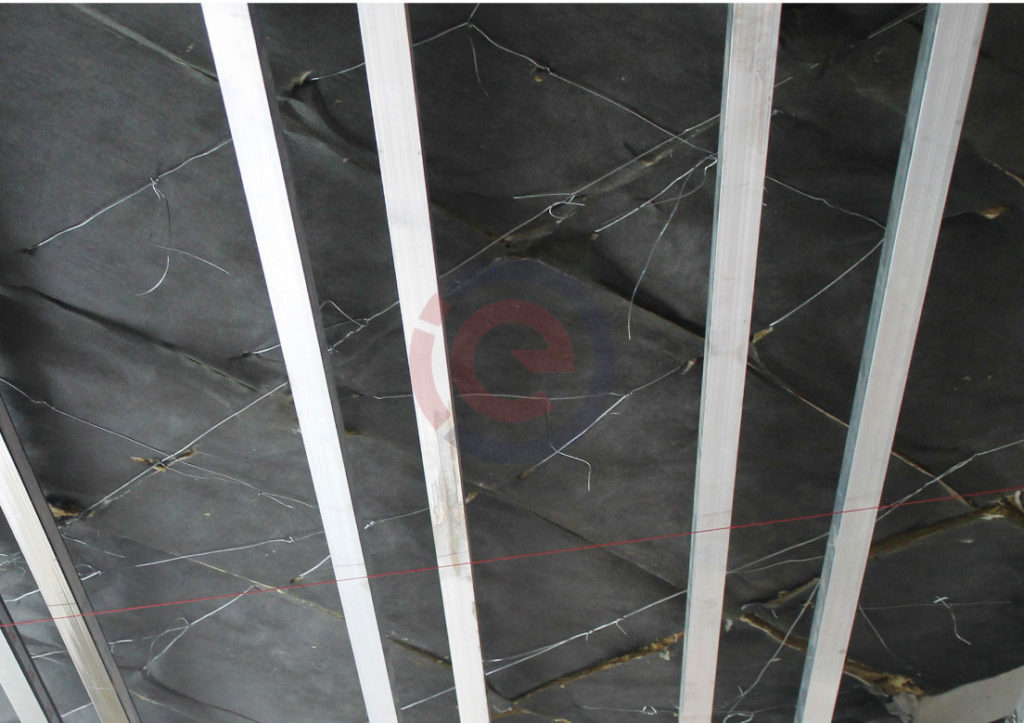

Resin bonded slab consist of long fine fibres spun from molten natural rocks, bonded with a thermosetting resin slab which provides excellent thermal insulation, fire protection and sound absorption.

Incombustible when tested as per IS: 3144 melting point of fibre is above 1000 ° C. Complying with BS – 476 Part 4 and ASTM E -136.