Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Brochure

Download our document to see specific data of the service and how we work.

PRE-ENGINEERED BUILDINGS ARE IN

Pre-Engineered Buildings (PEB) are the need of the hour these days. It is the most sought after structure, thanks to their fast-paced construction support and cost effectiveness. From certain perspective, it is an efficient structure compared to RCC due to light weight. They are also more resilient to seismic activities than RCC structures as they are made from metal.

METALS IN PEB HEAT UP

But metal has a higher thermal conductivity and lower thermal resistance than other building materials. Being a good conductor of heat, metal absorbs heat through the day. When it saturates its thermal absorption capacity, it starts releasing the heat to inert ambiences. Metal roofs do this at a faster rate. This increases the temperature of the space below and creates thermal discomfort. Due to continuous transfer of the heat, cooling load requirement increases and ultimately increases the energy bills.

- PEBs are in high demand for faster construction and cost effectiveness

- But the metals in PEB heat up the inside of the building faster

- This increases cooling load and energy bills

INROOF RAISES BARRIERS TO HEAT TRANSFER

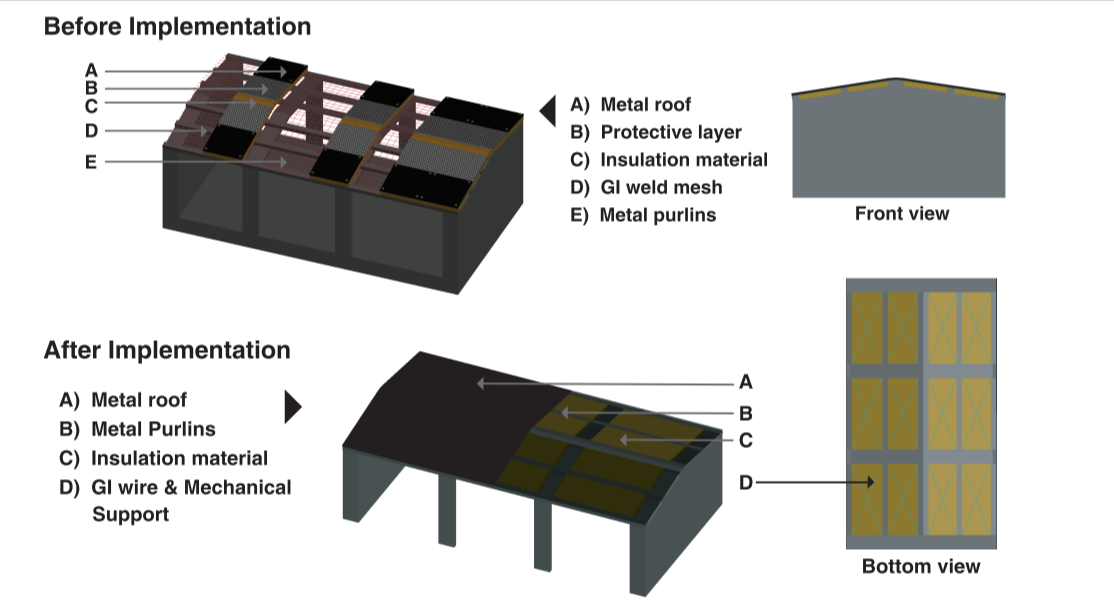

Insulation materials can be introduced during construction to reduce this disadvantage of PEBs. This can be done in two ways: when the metal roof is being implemented or when metal roof has already been implemented.

When Metal Roof is Being Implemented

In the first case, metal roof insulation system is implemented during the initial phase. Gl weld mesh is placed on the whole metal frame structure which is used as a base for the insulation material. Metal roof is laid on top of this insulation material hence locking it in place. The entire system is secured in place with the help of screw washer.

After Metal Roof is Implemented

In the second case, roof insulation system is implemented after the metal roof structure has been constructed. Here, metal roof works as the top layer for the insulation material. The material is placed between the metal purlins and is fixed with Gl wire and mechanical support system.

Saves Energy Bills

InRoof application on or below the roof reduces the temperature and ultimately provides comfort inside rooms. Lower temperature leads to savings in energy which in turn reduces energy bills. Another benefit is having an additional layer of protection. Roof insulation will protect the roof from the incursion of natural elements over the years. The suggested thickness here is between 4 mm to 50 mm.

Ideal For

Warehouses, Farmhouses, Parking Bays, Open Air Shopping Areas, Industrial Sheds, etc.

- InRoof Systems prevent the insides of buildings from being heated up

- This helps reduce energy consumption and bills

- It also adds a layer of protection on the PEB structure