Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Brochure

Download our document to see specific data of the service and how we work.

BROCHURE.DOC

1.25M

BROCHURE.PDF

3.81M

DESCRIPTION OF MATERIAL:

INNER FLEX is closed cell flexible elastomeric foam made from Nitrile rubber. Flexible, durable and easy to handle Class 1 fire safety as per BS 476 part 7. It is applicable in various fields such as HVAC, automobile, construction industry. pharma industry, hotels, hospital and cold storage industry.

| BRIEF DESCRIPTION | It is a closed cell thermal insulation material with class 1 fire classification. It ensures the energy saving in an eco-friendly manner as it is free from CFC/HCFC. |

|---|---|

| MATERIAL TYPE | Elastomeric foam based on synthetic rubber (NBR) |

| COLOR | Black |

| PRODUCT RANGE | Available in rolls (sheet) in 6mm, 9mm, 13mm, 16mm, 19mm, 25mm & 32mm thickness. Available in tubes from 6mm to 19mm & 25mm to 32mm thickness. |

| APPLICATIONS | HVAC, VRF and Plumbing application, Solar industry, Automobile sector, construction industry, pharma industry, hotels, hospital and cold storage industry to reduce heat loss or gain. |

TECHNICAL DATA

| SURFACE SPREAD OF FLAME | Class 1 - As per BS 476 Part 7 |

|---|---|

| RATE OF BURNING | Class V-0A - per UL94-1997 |

| PRACTICAL FIRE BEHAVIOUR | Self-extinguishing, does not drip, does not spread flame. As per ASTM D 635-06 |

TECHNICAL DATA

| DENSITY | 40-60Kg/m³ |

|---|---|

| TEMPERATURE RANGE | Max. service temperature +105°C Min. service temperature -40°C |

| THERMAL CONDUCTIVITY (W/M K) | Ø (°C) - 20°C: ≤ 0.035 W/mK |

| Ø (°C) - 30°C: ≤ 0.037 W/mK | |

| WATER VAPOUR DIFFUSION RESISTANCE FACTOR | ≥ 7000 (PLAIN) - As per ASTM E 96 |

| ECOLOGICAL DATA | No asbestos, No CFC-HCFC, No formaldehyde etc. |

INNER FLEX Class 1 Features:

- Class 1 fire performance

- Low thermal conductivity

- High water vapour diffusion resistance

- CFC/HCFC free.

- Easy to install

INNER FLEX Tubing (Class 1 Insulation Tube packing List)

| Size ID (mm) | Size (inch) | 6mm Thk | 9mm Thk | 13mm Thk | 19mm Thk | 25mm Thk | 32mm Thk | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pcs./Ctn | Mtr./Ctn | Pcs./Ctn | Mtr./Ctn | Pcs./Ctn | Mtr./Ctn | Pcs./Ctn | Mtr./Ctn | Pcs./Ctn | Mtr./Ctn | Pcs./Ctn | Mtr./Ctn | ||

| 6 | 1/4 | 250 | 457.5 | 156 | 285.48 | 10 | 01.3 | 54 | 98.82 | - | - | - | - |

| 10 | 3/8 | 200 | 366 | 120 | 219.6 | 80 | 146.4 | 40 | 73.2 | 25 | 45.75 | - | - |

| 13 | 1/2 | 150 | 274.5 | 100 | 183.00 | 72 | 131.76 | 36 | 65.88 | 20 | 36.6 | - | - |

| 16 | 5/8 | 120 | 219.6 | 90 | 164.70 | 63 | 115.29 | 35 | 64.05 | 20 | 36.6 | 20 | 36.6 |

| 19 | 3/4 | 100 | 183 | 72 | 131.76 | 56 | 102.48 | 30 | 54.9 | 20 | 36.6 | 20 | 36.6 |

| 22 | 7/8 | 90 | 164.7 | 64 | 117.12 | 48 | 87.84 | 30 | 54.9 | 18 | 32.94 | 18 | 32.94 |

| 25 | 1 | 80 | 146.4 | 56 | 102.48 | 42 | 76.86 | 25 | 45.75 | 16 | 29.28 | 16 | 29.28 |

| 28 | 1 1/8 | 70 | 128.1 | - | 89.76 | 36 | 65.88 | 25 | 45.75 | 16 | 29.28 | 12 | 21.96 |

| 32 | 1 1/4 | 60 | 109.8 | 42 | 76.86 | 30 | 54.9 | 20 | 36.6 | 15 | 27.45 | 12 | 21.96 |

| 35 | 1 3/8 | - | - | 40 | 73.20 | 30 | 54.9 | 18 | 32.94 | 12 | 21.96 | 12 | 21.96 |

| 38 | 1 1/2 | - | - | 36 | 65.88 | 25 | 45.75 | 16 | 29.28 | - | - | - | - |

| 42 | 1 5/8 | - | - | 30 | 54.90 | 25 | 45.75 | 16 | 29.28 | 12 | 21.96 | 10 | 18.3 |

| 45 | 1 3/4 | - | - | 30 | 54.90 | 20 | 36.6 | - | - | - | - | - | - |

| 48 | 1 7/8 | - | - | 28 | 51.24 | 20 | 36.6 | 15 | 27.45 | 10 | 18.3 | 10 | 18.3 |

| 51 | 2 | - | - | 24 | 43.92 | 20 | 36.6 | 12 | 21.96 | 9 | 16.47 | 8 | 14.64 |

| 54 | 2 1/8 | - | - | 21 | 38.43 | 20 | 36.6 | 12 | 21.96 | 9 | 16.47 | 6 | 10.98 |

| 57 | 2 1/4 | - | - | 20 | 36.60 | - | - | - | - | - | - | - | - |

| 60 | 2 3/8 | - | - | 20 | 36.60 | 18 | 32.94 | 10 | 18.3 | 9 | 16.47 | 6 | 10.98 |

| 63 | 2 1/2 | - | - | 20 | 36.60 | 15 | 27.45 | 10 | 18.3 | - | - | - | - |

| 67 | 2 5/8 | - | - | 18 | 32.94 | 15 | 27.45 | 9 | 16.47 | 8 | 14.64 | 6 | 10.98 |

| 73 | 2 7/8 | - | - | 18 | 32.94 | 13 | 23.79 | 9 | 16.47 | 8 | 14.64 | 6 | 10.98 |

| 76 | 3 | - | - | 18 | 32.94 | 12 | 21.96 | 8 | 14.64 | 8 | 14.64 | 5 | 9.15 |

| 79 | 3 1/8 | - | - | 16 | 29.28 | 12 | 21.96 | 8 | 14.64 | 8 | 14.64 | 5 | 9.15 |

| 84 | 3 1/3 | - | - | - | - | - | - | - | - | 6 | 10.98 | - | - |

| 89 | 3 1/2 | - | - | 16 | 29.28 | 12 | 21.96 | 6 | 10.98 | 6 | 10.98 | 5 | 9.15 |

| 102 | 4 | - | - | - | - | - | - | 4 | 7.32 | 5 | 9.15 | 4 | 7.32 |

| 108 | 4 1/4 | - | - | - | - | 8 | 14.64 | 4 | 7.32 | 4 | 7.32 | 4 | 7.32 |

| 114 | 4 1/2 | - | - | - | - | - | - | - | - | - | - | 2 | 3.66 |

INNER FLEX® Continuous Sheet (Class 1 Nitrile Insulation sheet packing List)

| Sheet Thickness (mm) | Dimensions | Roll content sq. mtr. |

|---|---|---|

| 6 | 1 X 15m | 15 |

| 9 | 1 X 15m | 15 |

| 13 | 1 X 15m | 15 |

| 16 | 1 X 15m | 15 |

| 19 | 1 X 15m | 15 |

| 25 | 1 X 10m | 10 |

| 32 | 1 X 8m | 8 |

INNER FLEX® Continuous Sheet (Class 1 Nitrile Insulation sheet packing List)

SOLAR SYSTEM PIPEWORK

- Due to high demand & cost of energy and its effect on environment, community & businesses are converting into solar heating system.

- Large amount of heat is lost from pipes that connects the solar panel to hot water tanks and heat pumps. Which reduces overall efficiency of system i.e. less energy is harnessed.

- To reduce that heat loss, the pipe carrying hot water needs to be properly insulated.

- The solar system pipework is long and carrying water at temperature of 60-75°C or more in some commercial applications, as well as it is located outside so insulation material used shall be resistant to moisture, and damage by birds etc.

- INNER FLEX tube or sheet with tough, UV resistant outer covering is ideal solution for solar hot water system pipework.

PLUMBING APPLICATION: HEATING & COOLING

- Plumbing covers the hot and cold water supply lines in case of residential & commercial applications like hotels, hospitals etc.

- The plumbing lines pass through both indoor and outdoor locations.

- Insulating these lines will save large amount of energy and ultimately decreases load on heating/cooling system energy consumption drastically.

- The insulation in case of cold water line prevent it from freezing at sub-zero temperature, also helps in condensation control which avoids corrosion of pipe surface.

- Insulating hot water pipe prevent heat loss to surrounding air which help in reduction of carbon emission.

- INNER FLEX tubing is working well for cold as well as for hot water lines due to its good service temperature range.

VRV/VRF piping in Split Air conditioning System

- A new kind of HVAC system uses VRV/VRF technology which increases effectiveness and efficiency.

- Due to this it has become good option for certain commercial & residential construction projects that requires high levels of flexibility when it comes to occupants comfort or for retrofit projects.

- The term VRF/VRV refers to ability of system to control the amount of refrigerant flowing to each of the evaporators with different capacities & configuration in simultaneous heating and cooling in different zones and heat recovery from one zone to another.

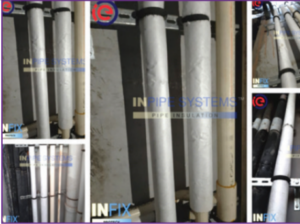

- Most of the VRV/VRF system consist of 3 –pipe system which are made up of copper or Aluminium, all of which requires to be insulated.

- These 3 pipe system (liquid line, hot gas line & suction line) branched off with solenoid valve that also needs to be insulated. These set of pipes requires insulating, usually place within a small space or in an exposed area. So insulation material shall be clean free from dust & fibres and formaldehydes.

- In normal operating condition, the temperature of VRV/VRF pipe system ranges from -160 C to 700 C, so here closed cell elastomeric insulation is applicable.

- INNER FLEX tubing service temperature ran ges from -40°C to 105°C, which provides best option for VRF piping insulation.

Ductwork Application

- Ductwork refers to the system of ducts and pipes that circulate heated or cooled air throughout the serving area.

- Ducts are made up of thin material, usually sheet metal, which causes air to leak. So proper insulation will help to maintain temperature and avoid leakage. The ductwork in unconditioned area such as basement, ceilings and floors is where ductwork insulation is most important.

- In case of cooled air passing through warm areas can cause condensation in the ductwork. This condensation leads to development of moisture formation on the surface of duct causing mould growth, corrosion.

- To address these issues and maintain temperature of heated or cooled air the different shapes duct needs to be insulated.

- To address these issues and maintain temperature of heated or cooled air the different shapes duct needs to be insulated.

- Inner Engineering provides closed celled elastomeric insulation INNER FLEX sheet which is dust and fibre free, free from CFC/HCFC having high water diffusion resistance factor helps to prevent wastage of energy, leaks, temperature drop and mould growth without harming environment.

- Ductwork refers to the system of ducts and pipes that circulate heated or cooled air throughout the serving area.

- Ducts are made up of thin material, usually sheet metal, which causes air to leak. So proper insulation will help to maintain temperature and avoid leakage. The ductwork in unconditioned area such as basement, ceilings and floors is where ductwork insulation is most important.

- INSEAL Alu tapes can be used to seal the joints of insulation sheet, which gives proper covering to prevent heat loss through gaps.

Valves, Fittings and Supports:

- Pipework is coming with different types of Valves & fittings which also contribute to heat loss or heat gain in the overall process.

- But, due to complicated cutting & installation requirement people avoid applying insulation.

- This leads to almost 20-30% loss of heat. So insulation of valves & fittings is also most important parameter to save energy in process

- INNER FLEX tubing service temperature ran ges from -40°C to 105°C, which provides best option for VRF piping insulation.

- In HVAC application pipe support becomes a weak part while insulating pipe surface, as it creates a thermal bridge which causes unnecessary heat loss in hot application.

- In cold application uninsulated pipe support will leads to condensation problem.

- So applying INNER FLEX sheets by proper cutting and installation will help to reduce above problems, as it’s a good water vapour resistant.

ADHESIVE - INBOND

- For installing insulation material properly over surface Inner Engineering provides with one of its best adhesive solution

TAPES - INSEAL SELF ADHESIVE TAPE

- ALU TAPE, GC TAPES are used to seal the insulation joints for proper installation.