Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

Brochure

Download our document to see specific data of the service and how we work.

BROCHURE.DOC

1.25M

BROCHURE.PDF

3.81M

INWOOLTM FIBRE GLASS

INWOOLT™ is open cell & lightweight glass wool having low thermal conductivity, high sound absorption and excellent fire performance. It consists of inorganic glass fibres bonded together with high temperature binders

INWOOL

| Brief Description | INWOOL™ is glass wool made from sand, soda ash, and limestone with a high proportion of recycled glass & other minerals. These are melted, spun into fibers, and mixed with organic resins before curing into products. |

|---|---|

| Material Type | Open cell material having good thermal, acoustic & fire properties. |

| Color | Light Gold |

| Applications | AHU Rooms, Air ducts, Home theatres, Multiplexes, Recording studios, PEB structures, Machinery enclosures, etc. |

STANDARD DIMENSIONS:

| Thickness (mm) | Density (kg/m³) | Length (m) | Width (m) | Facing |

|---|---|---|---|---|

| 25 & 50 | 16/24/32/48 | 7.5 to 20* | 1.2 | Plain, FSK |

THERMAL CONDUCTIVITY (K VALUE) TABLE (AS PER IS 15402/IS 3346):

| Mean Temperature (°C) | Thermal Conductivity (W/mK) | |||

|---|---|---|---|---|

| 16 | 24 | 32 | 48 | |

| 35 | 0.0459 | 0.0455 | 0.0392 | 0.0358 |

| 50 | 0.0509 | 0.0506 | 0.0432 | 0.0392 |

THERMAL RESISTANCE(R VALUE) TABLE:

| Mean Temperature (°C) | Minimum Thermal Resistance (hr.ft². °F/BTU) - 50 mm Thickness | |||

|---|---|---|---|---|

| Density (kg/m³) | ||||

| 16 | 24 | 32 | 48 | |

| 35 | 6.18 | 6.23 | 7.27 | 7.93 |

| 50 | 5.57 | 5.61 | 6.57 | 7.24 |

THERMAL RESISTANCE(R VALUE) TABLE:

| Temperature Range | -195°C to 230°C |

|---|---|

| Fire Performance | Fire Propagation: Class 0 (As per BS 476 - Part 6 & 7) |

| Surface Spread of Flame: Class 1 (As per BS 746 - Part 7) | |

| Surface Burning Characteristics: Class A (As per ASTM E84) | |

| Incombustibility | 4.62% (As per IS: 3144:1992 - Method 16) |

| Recovery After Compression | 96.6% (As per IS 8183:1993 - Annex A) |

| Noise Reduction Coefficient (NRC) | 0.9* (As per ASTM 423C/ISO 354) |

| Asbestos Analysis | No Asbestos (As per JIS 1481:2016 & 2018) |

*Result may vary as per density of material

FEATURES

- Light weight

- Low thermal conductivity

- Good sound absorption

- High temperature application

- Wide temperature range

- Non-combustible material

- Excellent fire performance

- Easy to cut & install in critical areas due to its flexibility

INWOOL™ APPLICATION AREA:

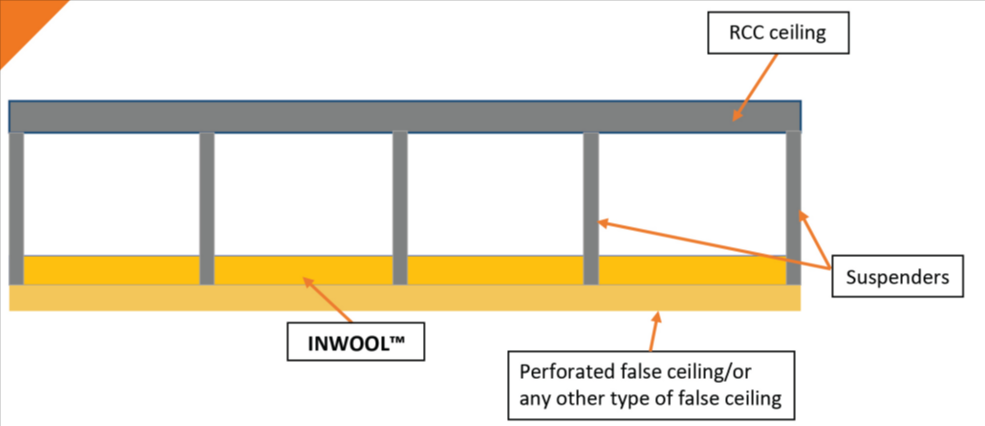

FALSE CEILING INSULATION APPLICATION:

- INWOOL™ shall be kept directly over perforated false ceilings of gypsum, mineral fibre etc. to create a proper hearing ambience inside the room for the occupants by preventing echo.

- If these rooms are exposed to terrace then there are chances that the heat transfer can take place from ceiling to the room which will increase the energy consumption of the air conditioning room.

- INWOOL™ will help to reduce the heat transfer inside the room from the ceilings & energy consumption can be reduced & it helps in providing human comfort.

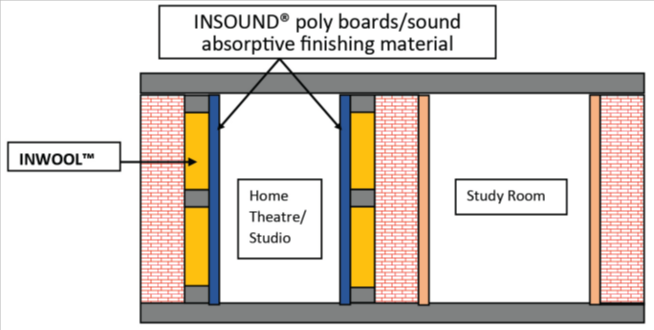

HOME THEATRE/STUDIO APPLICATION:

- Home theatres are meant to be built for entertainment purpose. But if they are not insulated proper acoustically then there are chances that echo develops inside the theatre creating inappropriate hearing ambience inside it for the occupants.

- Also, there are chances of sound transmitting from the theatre to other rooms; hence it should be properly insulated to not allow the sound to transmit to other rooms.

- INWOOL™ having good NRC value shall be fixed on the wall of the Home theatre along with the finishing material such as INSOUND® poly boards such that it will create a proper hearing ambience inside the home theatre.

- Recording studios are built in such a way that it could block any kind of unwanted sound coming from the outside as well as prevent echo inside the studio to create a proper acoustic ambience inside it & can solve the purpose for which it is meant for.

- INWOOL™ having good sound absorption coefficient shall be fixed on the walls of the Recording studio along with the finishing material such as INSOUND® poly boards such that it will prevent echo inside the studio.

- INWOOL™ having low thermal conductivity will also help to reduce the heat transfer inside the Home Theatre/Recording Studio from the walls, reducing energy consumption & helps in providing human comfort.

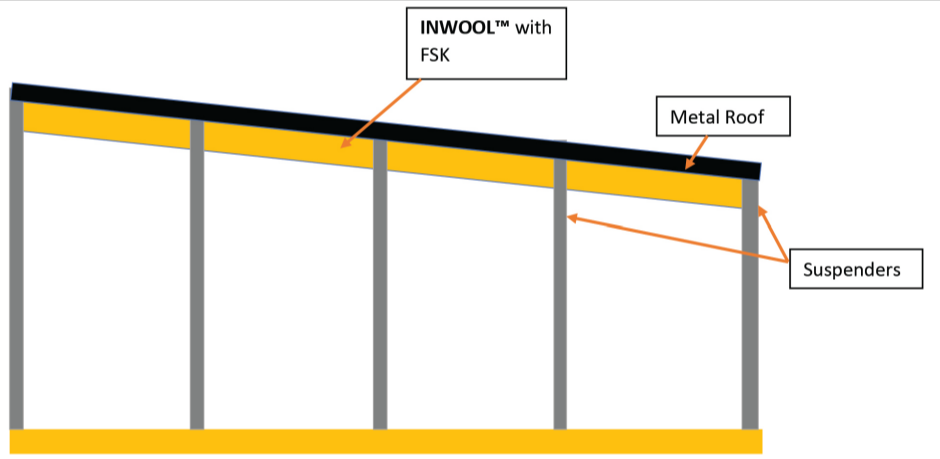

- The roof of many industrial & commercial buildings is made of metal. As metals have much higher thermal conductivity, metal roofs become the primary aspects of heat gain inside the buildings.

- INWOOL™ with FSK having low thermal conductivity when applied under the metal roof will help to reduce the rate of heat transfer inside the building from the metal roof, creating an appropriate working ambience for the workers inside the building.

- INWOOL™ with FSK having low thermal conductivity when applied under the metal roof will help to reduce the rate of heat transfer inside the building from the metal roof, creating an appropriate working ambience for the workers inside the building.

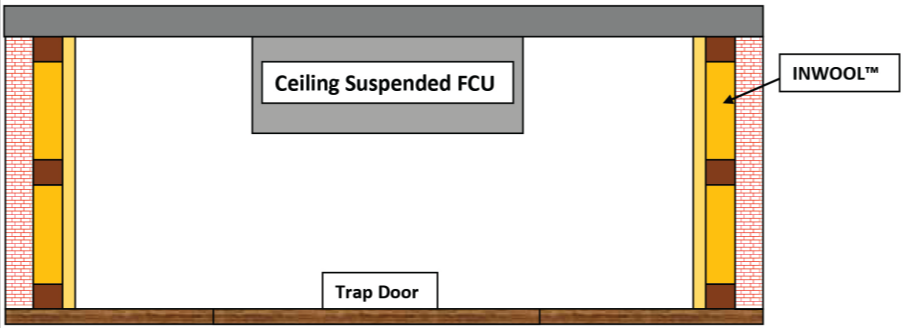

- Trap door is hinged/sliding door in a floor or ceiling where Fan Control Unit (FCU) is concealed.

- Trap door acoustic insulation ensures absorption of the noise generated by FCU. This is done in order to not let the noise of the FCU transmitted to other side of trap door.

- It also reduces vibrations transmitted from installation area.

AHU ROOM APPLICATION:

- There is an AHU room where Air Handling Unit (AHU) is placed and it generates a lot of noise. This Sound is transmitted to other rooms and creates discomfort among occupants in other rooms.

- INWOOL™™ shall be fixed on the wall of an AHU room to reduce the sound transmission & makes the surrounding comparatively noise free.

- AHU placed inside of a room can generate heat. The use of INWOOLT™ is adding advantage in reduction of heat transfer from that room to other room by applying it on the wall and acting as a thermal barrier between two rooms which helps in maintaining comfort level inside of other rooms.

- Above mentioned applications are for reference purpose only. They can be modified as per requirement.

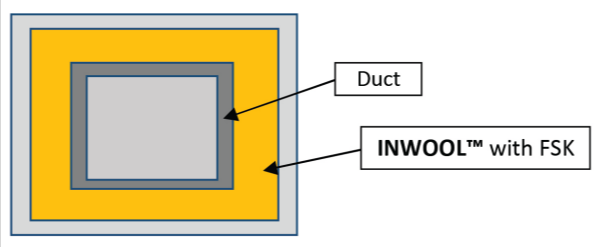

DUCT THERMAL APPLICATION:

- Ducts are one of the important aspects of HVAC systems as they are used to carry hot/cold air.

- INWOOL™ having good thermal conductivity wrapped over ducts to maintain temperature of air by reducing heat transfer.

- INWOOL™ having good fire performance resist spread of fire & prevent any hazardous situations causing due to fire.

INWOOLT™ FIBRE GLASS

- INWOOL™ Encapsulated bags are open cell & lightweight glass wool wrapped in readymade bags.

- It is used for Thermo-Acoustic purpose, where good sound absorption is required to prevent echo inside the room & minimum heat transfer is required to reduce energy costs by reducing energy consumption & ultimately providing human comfort.

- Base material consists of inorganic glass fibres bonded together with high temperature binders.

INWOOL™ Encapsulated Bags:

| Brief Description | INWOOL™ Encapsulated bags is a glass wool wrapped in readymade bag which is three side machine stitched and one side open end with hook and loop fasteners. This specific grade is used for thermo-acoustic applications. |

|---|---|

| Material Type | Light weight material having good thermal and acoustic property |

| Color | Black |

| Applications | AHU Rooms, Home theatres, Multiplexes, Recording studios, PEB structures, Machinery enclosures, etc. |

STANDARD DIMENSIONS:

| Thickness (mm) | Density (kg/m³) | Length (m) | Width (m) |

|---|---|---|---|

| 25 & 50 | 16/24 | 1000 | 600 |

THERMAL CONDUCTIVITY (K VALUE) TABLE (AS PER IS 15402/IS 3346):

| Mean Temperature (°C) | Thermal Conductivity (W/mK) | |

|---|---|---|

| Density (kg/m³) - 16 | Density (kg/m³) - 24 | |

| 25 | 0.0429 | 0.0423 |

| 35 | 0.0459 | 0.0455 |

THERMAL RESISTANCE (R VALUE) TABLE:

| Mean Temperature (°C) | Minimum Thermal Resistance (hr.ft².°F/BTU) - 50 mm Thickness | |

|---|---|---|

| Density (kg/m³) - 16 | Density (kg/m³) - 24 | |

| 25 | 6.61 | 6.71 |

| 35 | 6.18 | 6.23 |

TECHNICAL DATA:

*Result may vary as per density of material

| Property | Value | Standard |

|---|---|---|

| Recovery After Compression | 96.6% | As per IS 8183:1993 (Annex A) |

| Noise Reduction Coefficient (NRC) | 0.9* | As per ASTM 423C/ ISO 354 |

| Asbestos Analysis | No Asbestos | As per JIS 1481:2016 & 2018 |

THERMAL RESISTANCE (R VALUE) TABLE:

- Light weight

- Low thermal conductivity

- Good sound absorption

- Good acoustic & thermal property

- Asbestos free

INWOOLT™ ENCAPSULATED BAGS APPLICATION AREA:

FALSE CEILING INSULATION APPLICATION:

- INWOOL™ Encapsulated bags shall be kept directly over perforated false ceilings of gypsum, mineral fibre etc. to create a proper hearing ambience inside the room for the occupants by preventing echo.

- If these rooms are exposed to terrace then there are chances that the heat transfer can take place from ceiling to the room which will increase the energy consumption of the air conditioning room.

- INWOOLT™ Encapsulated bags will help to reduce the heat transfer inside the room from the ceilings & energy consumption can be reduced & it helps in providing human comfort.

HOME THEATRE/STUDIO APPLICATION:

- Also, there are chances of sound transmitting from the theatre to other rooms; hence it should be properly insulated to not allow the sound to transmit to other rooms.

- INWOOL™ Encapsulated bags having good NRC value shall be fixed on the wall of the Home theatre along with the finishing material such as INSOUND poly boards such that it will create a proper hearing ambience inside the home theatre.

- Recording studios are built in such a way that it could block any kind of unwanted sound coming from the outside as well as prevent echo inside the studio to create a proper acoustic ambience inside it & can solve the purpose for which it is meant for.

- INWOOL™ Encapsulated bags having good sound absorption coefficient shall be fixed on the walls of the Recording studio along with the finishing material such as INSOUND poly boards such that it will prevent echo inside the studio.

- INWOOL™ Encapsulated bags having low thermal conductivity will also help to reduce the heat transfer inside the Home Theatre/Recording Studio from the walls, reducing energy consumption & helps in providing human comfort.

- The roof of many industrial & commercial buildings is made of metal. As metals have much higher thermal conductivity, metal roofs become the primary aspects of heat gain inside the buildings.

- Due to high heat gain inside the building through metal roof it creates an inappropriate working ambience for the workers inside the building. So it becomes necessary to insulate the metal roofs thermally to prevent heat gain inside the building through metal roofs.

TRAP DOOR APPLICATION:

- Trap door is hinged/sliding door in a floor or celling where Fan control Unit (FCU) is concealed

- Trap door acoustic insulation ensures absorption of the noise generated by (FCU). this is done in order to not let the noise od the FCU transmitted to other side of trap door.

- It also reduces vibrations transmitted from installation area.

AHU ROOM APPLICATION:

- INWOOLT™ Encapsulated bags shall be fixed on the wall of an AHU room to reduce the sound transmission & makes the surrounding comparatively noise free.,

- AHU placed inside of a room can generate heat. The use of INWOOL™™ Encapsulated bags is adding advantage in reduction of heat transfer from that room to other room by applying it on the wall and acting as a thermal barrier between two rooms which helps in maintaining comfort level inside of other rooms.

- Above mentioned applications are for reference purpose only. They can be modified as per requirement.